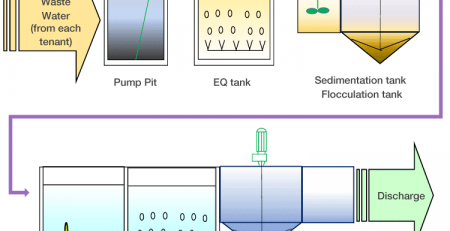

Wastewater treatment system

About sewage

Water that has entered it as a result of any use of foreign substances is called sewage. The human need for various types of water consumption, both in the health sector and in the industrial sector, has caused the volume of wastewater produced by various centers to increase every day. Due to the presence of various substances and impurities in the wastewater, their direct discharge to receiving sources such as surface water from wells and agricultural lands causes their double pollution and endangers the health of the organisms that live in their vicinity.

Therefore, to prevent environmental pollution and maintain the health of humans and other living things on Earth, a variety of environmental standards have been developed and implemented in many countries with laws and regulations. According to the country’s environmental standards, wastewater can be discharged to three receiving sources after treatment, which are: 1- Surface water 2- Agricultural use and irrigation of green space and 3- Absorbent well. Due to the different ability of each of these sources to accept different types of pollution, the restrictions imposed on them are not the same. For example, for discharging nitrate to agricultural uses, no limiting concentration is considered, while for discharging the same wastewater to surface water, it is necessary to reduce the nitrate concentration to 50 mg / l. Therefore, determining and selecting the receiving source has an essential role in the design and construction of various wastewater treatment systems. Also, wastewater can be divided into two categories in terms of quality: sanitary and industrial wastewater.

Activated sludge method

Activated sludge method, which is a biological method, is one of the most important methods of wastewater treatment. In this method, oxygen, which is necessary for the life and activity of the biological mass originating from the microorganism and bacteria community in the wastewater, is artificially blown into the wastewater with two surface and deep ventilation method, causing the growth and reproduction of microorganisms and the organisms decompose the wastewater. To achieve a high treatment efficiency, there must always be a good ratio between the amount of microorganisms and the amount of organic matter in the waste water. For this purpose, some of the sludge separated in the settling tank is always returned to the aeration tank called activated sludge. This method is mostly used in factories and cities for the treatment of sanitary waste water.

The activated sludge method is a modified version of the activated sludge method with extensive aeration. Due to the fact that in small communities, the volume of wastewater production is not enough to build a sludge digester, it is minimized by aerating the wastewater and increasing the residence time of the wastewater. Due to the advantages of this method, activated sludge method with extensive aeration is the most common method for sanitary wastewater treatment in villas and residential complexes, restaurants, hospitals, training centers, hotels and tourist centers, labor camps of factories, companies and companies.

Sanitary sewage

Wastewater that is produced as a result of daily human activities is called human wastewater. Since most of the water is used in human activities for sanitary purposes, these wastes are also called sanitary wastes. The quality and quantity of these wastewaters are highly influenced by the general culture and way of life of human beings in each region, but at the same time their qualitative changes in a limited area are usually very small.

Industrial wastewater

Waters that have changed their quality as a result of their use in an industrial process are called wastewater with industrial effluents. Today, water is used as a cooling or solvent rinse in almost all industrial processes. During the use of water in industry, foreign substances often enter the water stream in solution or suspension and change the water quality. If the concentration of these substances exceeds the allowable level, it is necessary to treat the wastewater for disposal to the receiving sources. Unlike sanitary wastewater, wastewater produced in different industries has a very different quality. It is even possible that the industrial wastewater of two units producing a similar product is different from each other, which is due to the type of production process.

Pre-treatment

All operations that take place before performing a main treatment process are called pre-treatment. Due to the fact that all treatment methods have a limited capacity, therefore, it is always tried to prepare the quality conditions of wastewater to enter the main treatment system with the help of pre-treatment. Although pre-treatment methods are generally simple and inexpensive, none of them are capable of complete wastewater treatment and, as mentioned, their purpose is to perform a preliminary treatment.

The most important pre-treatment methods are:

1 – bar screen wastewater

2- Suspended particle removal unit

3- Septic tank

4- Degreasing

bar screen wastewater

To prevent problems caused by coarse particles and suspended grains that are present in the wastewater and cause problems in electromechanical installations and clogging in the pipes, it is necessary to separate these particles from the wastewater. This operation is performed by the waste disposal unit. Waste removers are made in different types and capacities, which are designed and manufactured according to the wastewater discharge pH of the particle diameter and manual or mechanical cleaning and local operating conditions.

Removal of fat and oil from wastewater

One of the operations used to separate solid or liquid particles from a liquid phase is called degreasing. In industrial wastewater, we see large amounts of fatty oils and suspended solids in the wastewater. Discharge of such wastewaters to absorption wells causes clogging of absorption wells and severe pollution of groundwater and surface water sources. Due to the low mass volume and lightness of fats and oils, the flotation method is used to remove fats.

The most important methods of removing fat and oil are the following:

CPI (corrugated plate interceptor)

API (American Petroleum Institute)

DAF (dissolved air flotation)

Leave a Reply